Unconventional Knowledge About Window Boxes

- Monica Harper

- Nov 11, 2019

- 5 min read

Window boxes are designed for taking a peek at the product throughout the boxes. Basically, packaging is representing the products from decades which is indeed enhancing its quality on daily basis.

Usually, custom window cut boxes are used on cosmetic products, toys, soaps, bakery goods, electronic goods, etc. The beneficial factor of custom window boxes provides customers the conditions of the products from the seal packaging.

Therefore, it is very important that the materials used to maintain the custom window boxes should sturdy by nature. Because, the quality of the boxes matters a lot in the market.

However, custom window boxes are used by the products which get sold on daily basis and they hare displayable. For instance, soaps, toys, cosmetics, etc.

The materials used to manufacture the custom window packaging boxes are Kraft, Cardstock and Corrugated. Furthermore, there are subcategories of these custom box materials.

Custom window boxes used for many cultural and festivities. For instance, gifts for weddings, Birthdays, Anniversaries, Baby Shower, Bridal Shower, etc.

Materials used for Custom Window Boxes:

Kraft and cardstock the best materials used to manufacture custom window boxes of customized sizes and shapes. However, cardstock and Kraft have robust properties with grippy spaces that make the packaging top of the world. Because some products kept in bottles like perfumes which made up of glass so, the gripping packaging protects from tackling the side walls.

Kraft Window Box Packaging:

Kraft Packaging is one of the best-detailed packaging material. However, Kraft is made from strong pinewoods woods by which it has strongness weight lifting capability. More often, Kraft decorated by used different printing styles and add-ons too.

Because these products are fashionable and the best way to represent it is fashionable as well. How do we do that? Well, it's very simple that we just use the different coating on the whole packaging.

Coatings for Window Boxes:

There are three different types of coating which are gloss finishing, satin finishing, and matte finishing. Mostly matte finishing and satin finishing are more preferable for custom window packaging boxes. Because the matte finishing a smooth and satisfying touch to the box’s packaging and satin provides a silky-smooth finish that retains its pearl-like shine when dry.

Talking about the matte finishing, spot UV also used for displaying the name of the brand, the logo of the company. However, the details of the coating are mentioned below:

Matte Finishing:

Matte finishing is also known as “Flat” finishing. Because it has a flat surface with a dull look and can easily absorb light after getting dry. Matte is a smooth, subtle look and not gleam.

Satin Finishing:

Satin finishing provides semi-glow shiny effects. This satin finishing reflects light more than matte and stands up well while washing.

In addition, other than window cut custom boxes this used in homes such as bathrooms, the kitchen and a kid's room as well as on trim and molding throughout the house. This finish does not hide imperfections in surface or application; any touch-ups will stand out.

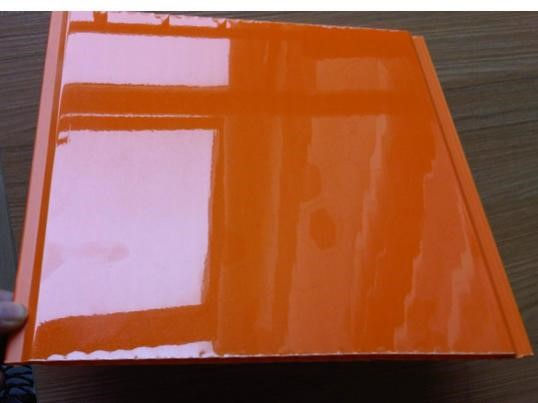

Gloss Finishing:

Gloss finishing gives a shiny look on the surface of the custom window boxes. Moreover, gloss or semi-gloss finishes prove durable and scrub-able, with semigloss offering high resistance to moisture.

Addons for Window Boxes:

Addons make the boxes glow in the market and industries. For instance, the addons make the boxes more decorated like using foiling paper with color customization. However, Embossing and Debossing is a process of printing images on the boxes in a way that the image raised or recessed on the paper or boxes. The embossing process displays the image has raised on the box and debossing is it's opposite.

Meanwhile, embossing held by pressing a sheet of paper into a female die that has a design engraved or etched into it. Moreover, custom window cuts, custom PVC/CPVC windows also used.

Manufacturing Styles of Custom Window Cut Boxes:

Die Cut Boxes

Glued Boxes

Die Cut Boxes: Die cut boxes are completely manual. It's just easy to shape the boxes using your bare hands. However, Packaging companies ship these boxes with die cuts on them so that they can be used easily.

Glued Boxes: Glued boxes are used very often for the manufacturing of custom window cut packaging boxes. The glue is used on the carve and joints of the boxes which makes the toughness so that the box can also be used for some other products as well.

Mind-Blowing Printing Techniques:

The printing process is their Knight in Shining Armor. Three of these materials are great with the printing processes which indeed helps to increase product productivity according to the market point of view.

However, there are two types of printing processes:

CMYK Printing

PMS Printing

RGB and HEX Printing

Spot UV

CMYK Printing Will Make You Tons of Cash. Here's How!

CMYK printing contains four colors from which the rest of the colors are evolved. Hence, CMYK is the best printing process for a big order such as wholesale custom window boxes. CMYK printing provides specific shades of one color which are used for printing more than one shade on custom-colored boxes. In conclusion, this printing process is cheap and the quality of printing is marvelous.

The Shocking Revelation of PMS Printing:

The PMS printing process is one of the top printing processes in the world. PMS printing contains millions of shades of a single color which helps a lot in evolving the best custom decorative boxes. PMS printing provides shade cards that help customers in the selection process of wholesale custom colored boxes.

The Innovative RGB and HEX Printing:

RGB and HEX both are onscreen printing processes. These types of printing used in case of designing the printing processes on a computer screen. It’s the simplest and easy to use category of the printing process. However, it used in HTML5 and CCS3 which is available on much coding software. Its coloring table is:

Beneficial Approaches related to your Business Perspective:

The major factor how the custom window printed boxes provide benefits to your brands and in which ways? Plus, what is there for the company to make the decisions? However, some marketing strategies help your brand to make an impact on the market.

Meanwhile, every day new products launched and if they follow the right path correctly it makes your brand’s demand more and more. Some productive steps will help your product throughout its journey.

The Latest Trend in Advertising of Custom Boxes:

Advertising is the best approach that helps your brand making a huge impact in the market place. However, use different styles of boxes that will help your product throughout the market.

For instance, glowing window boxes, small window boxes, corrugated window boxes, custom PVC window cut boxes, etc.

Here's What Industry Insiders Say About Shipping Boxes:

These customized boxes are dust resistant and protect the products from any physical activities. However, corrugated used for shipping purposes. Corrugated is smooth and flexible, sturdy, comfortable which helps in making the shipping experience better for you which incredibly makes you believe that your products are in good hands.

Packaging Bee is Innovating the Packaging Industry

The packaging bee is providing the best custom packaging boxes related to your products. There are multiple materials with different printing processes that suit the product’s outlook.

However, packaging bee owns a team of well-trained experts that are working day and night to make custom packaging experience better for you.

We also provide suggestions on the types of custom product boxes related to your products without any extra charges.

You can email us for any type of enquire info@packagingbee.com or call us at

Helpline +1-732-230-4272.

Comments